Picture this: A global medical device manufacturer misses a small but crucial update to its product labeling in Europe. The result? A product recall, millions lost, and significant damage to trust. Or consider a pharma company where a single error in batch release documentation delays a life-saving drug’s approval. These are not rare occurrences. They are the everyday risks of relying on manual processes in industries where accuracy and timeliness are everything.

For pharmaceutical companies, human error is more than just an inconvenience. It can derail timelines, invite regulatory scrutiny and penalties, and jeopardize market access. The solution many industry leaders are turning to is Process Automation — now increasingly powered by AI.

By embedding automation into critical workflows — and in many cases AI (including Agentic AI) — life sciences organizations move beyond simply eliminating manual mistakes. They begin to build intelligent, self-learning processes that can interpret data, detect risk, guide actions, and respond in real time.

Where Do Errors Come From?

Despite the best-trained teams, manual processes leave room for mistakes. In life sciences, these risks often show up in three key areas:

1. Manual Data Entry

In pharmaceutical research, clinical trials, and medical device testing, large volumes of information move across systems. Regulatory submissions, batch records, and clinical documentation often require teams to extract data from one system, export it into Excel, manipulate or reformat it, analyze it, and then manually import it elsewhere. Each of these steps introduces multiple points of failure—typos, broken formulas, missing fields, or mismatched records. With so much manual handling, especially during data transformation, the risk of errors increases significantly. In pharmaceutical manufacturing, even a single incorrect entry can halt production or delay approvals.

2. Inconsistent Processes

If different teams document a batch release or a device test in different ways, the results are unreliable. Without Process Automation, small inconsistencies can add up to costly deviations and compliance gaps. Discover how integrating LIMS with workflow automation reduces lab errors.

3. Compliance Oversight

Regulatory requirements for both Pharma and MedTech evolve constantly. Relying on humans to track and apply every update is time consuming and risky. A missed requirement or outdated guideline can trigger fines, recalls, and reputational harm. Here, regulatory compliance automation provides a strong safeguard.

Automation in Action: How Process Automation and AI Drive Impact

So how does Process Automation and AI make a real difference across life sciences operations? Here’s what it looks like in action:

Regulatory Submissions

Regulatory submissions involve multiple document sets, changing country requirements, and tight timelines — where even small errors can cause major delays.

Process Automation coupled with AI helps by:

- Pulling data automatically from clinical, safety, manufacturing, and regulatory systems

- Applying validation rules and AI-driven checks to flag gaps and inconsistencies early

- Automating version control, routing, and reviews

- Tracking submission status and triggering reminders or escalations for regulatory queries

Clinical Trial Feasibility and Site Selection

Manually selecting sites across fragmented data sources leads to delays and inconsistent decisions.

Process Automation and AI enable teams to:

- Aggregate trial, investigator, and epidemiology data into a unified view

- Apply scoring models to rank and shortlist sites

- Automate site questionnaires, reviews, and staffing workflows

- Monitor progress and reassign tasks dynamically

Global Label Change Management

Frequent label updates across markets are complex and prone to omissions.

Process Automation with AI supports:

- Automatic routing of label-change requests through review and approval workflows

- Built-in checks to ensure market-specific regulatory compliance

- Synchronization of global and local label versions

- Dashboards tracking version status and audit history

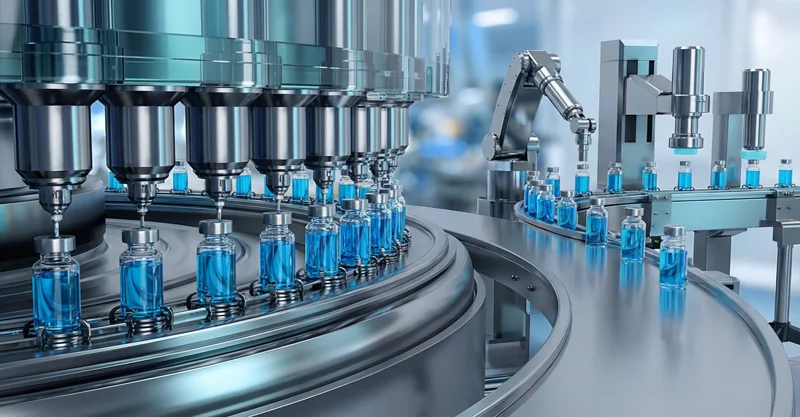

Clinical Supply Chain

Manual tracking increases the risk of shortages, waste, and compliance gaps.

Process Automation and AI help teams:

- Forecast demand using enrollment and historical trial data

- Track inventory in real time across depots and sites

- Trigger replenishment workflows when stock falls below thresholds

- Maintain traceability with automated logs and compliance checks

Real-World Evidence (RWE)

Fragmented, unstructured data slows insight generation.

Process Automation coupled with AI enables:

- Integration of EHRs, claims, registries, and patient data into unified workflows

- Automated data cleaning, validation, and standardization

- Faster generation of safety and effectiveness insights

- Audit-ready traceability for regulatory-grade RWE submissions

Study Data Access Management

Manual provisioning creates delays and security risk.

Process Automation with AI supports:

- Automated role-based access control

- Onboarding and offboarding of users and partners

- Dashboards showing who has access to what data

- Automated enforcement of GDPR, HIPAA, and other privacy rules

The Role of Expert Partners

Companies that smartly embrace automation don’t replace people but enable them to work smarter. But getting there isn’t always straightforward.

Many life science workflows have been built over years – patched, adjusted, and expanded until they’re full of extra steps and manual workarounds. And that’s where the real issues hide.

Legacy processes often come with:

- Too many handoffs, creating delays and unclear ownership

- Redundant checks driven by low trust in data and systems

- Disconnected tools that force teams into Excel-based workarounds

- Undocumented “tribal knowledge” that lives in people, not processes

- Patchwork compliance steps added over time, creating a maze of manual checks

- Slow, email-driven review cycles that invite errors

If these processes aren’t cleaned up first, automation just makes the inefficiencies move faster. The goal isn’t to automate chaos but eliminate it.

That’s why the real conversation shouldn’t begin with automation, but understanding how your processes actually run, what slows them down, and what needs to be simplified.

That’s where a strong process automation partner makes the difference. The right partner will:

- Simplify what you already have: Identify unnecessary steps, slow handoffs, recurring errors, and compliance risks.

- Lay out your workflows clearly: So teams see how things move today and how they should move going forward.

- Design automation-ready processes: Lean, logical workflows that are built for scale, not patchwork.

- Make automation work with your current systems: Whether it’s clinical, labeling, regulatory, or quality platforms.

- Keep compliance front and center: From validation to audit-readiness, ensuring nothing gets overlooked.

- Stay with you as things evolve: Because regulations update, priorities change, and automation must adapt along the way.

What’s Next? The Future of Process Automation in Life Sciences

AI is ushering in a new generation of Process Automation, one that is intelligent, predictive, and continuously improving.Instead of reacting to issues after they occur, life sciences organizations are beginning to build systems that can anticipate risk, adapt to change, and guide decisions in real time. Here’s what that next era looks like:

Intelligent Data Validation in Clinical Trials

AI Agents can continuously scan eCRFs, lab data, safety reports, and imaging outputs to flag inconsistencies, missing fields, and outliers as they appear, helping teams resolve issues long before database lock.

Predictive Oversight for Study Operations

By analyzing site performance, enrollment trends, protocol deviations, and monitoring findings, AI models can identify sites and studies at risk, enabling proactive interventions instead of reactive firefighting.

Adaptive Regulatory Compliance Monitoring

AI can track global regulatory updates and compare them against current submissions, labels, and operational processes, automatically alerting teams when changes impact ongoing studies or upcoming filings.

A Smarter, Safer Future for Life Science Processes

Errors are expensive, but they’re not inevitable. With Process Automation and AI, companies can dramatically reduce risk, ensure compliance, and build trust with regulators and customers. For life science leaders, the real question is no longer whether to automate, but how quickly you can evolve to intelligent, Agentic AI based Process Automation to stay ahead.